-

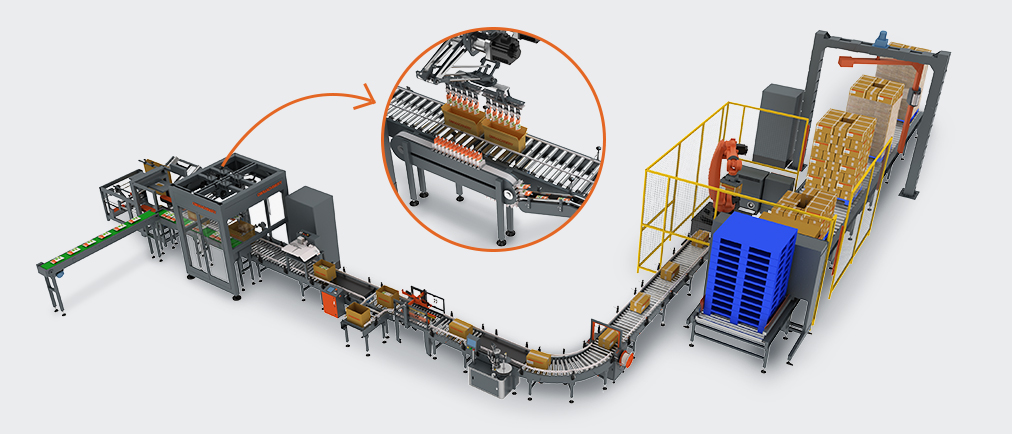

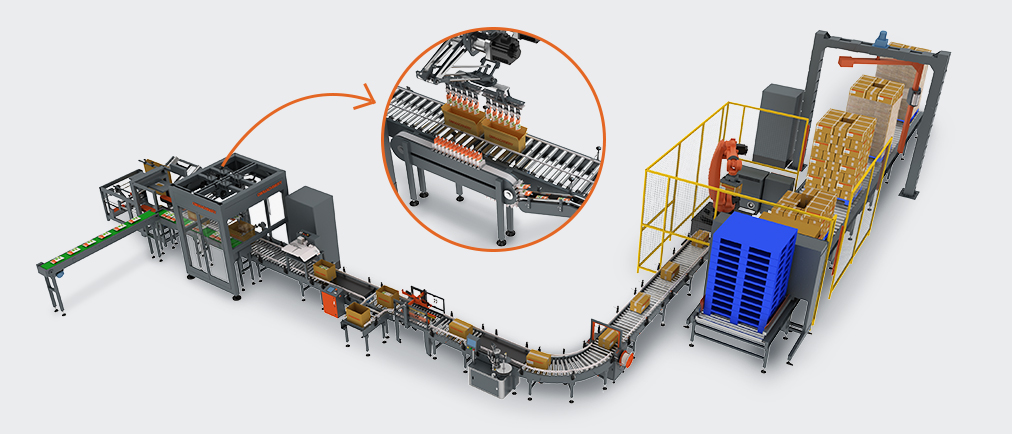

Wine Pouches Packaging Line With Coding System

1、Pouches feeding from filling & labeling machine:2、The system will delete the fail scanning pouch automatically:3、Servo feeding system:4、Carton erector :5、Robot top load the pouches vertically into the carton:6、8 pouches will generate one carton label and stick on the carton automatically :7、Tape carton sealer:8、The system will delete the fail scanning carton :9、108 cartons will generate one pallet label :10、User can check the pouch and carton relationship from the software :

Contact us and ask more

Message from users: the machine is very easy to use and the installation team is professional, serious and responsible

-

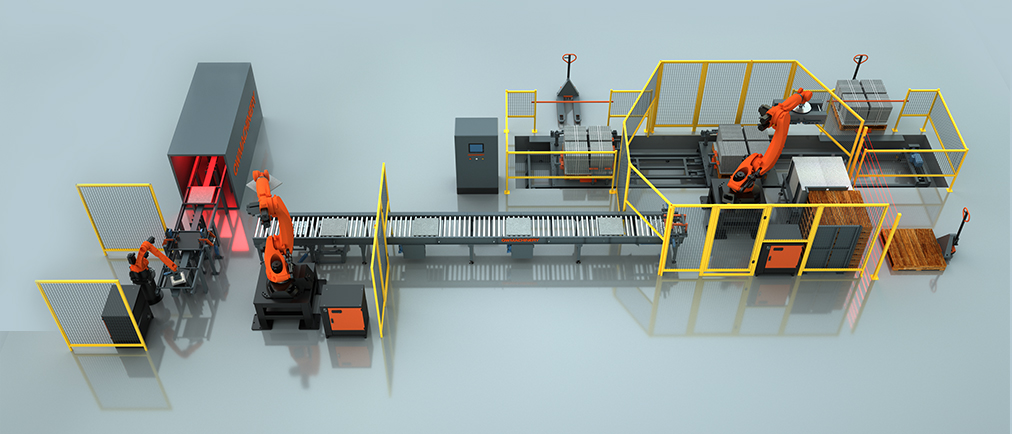

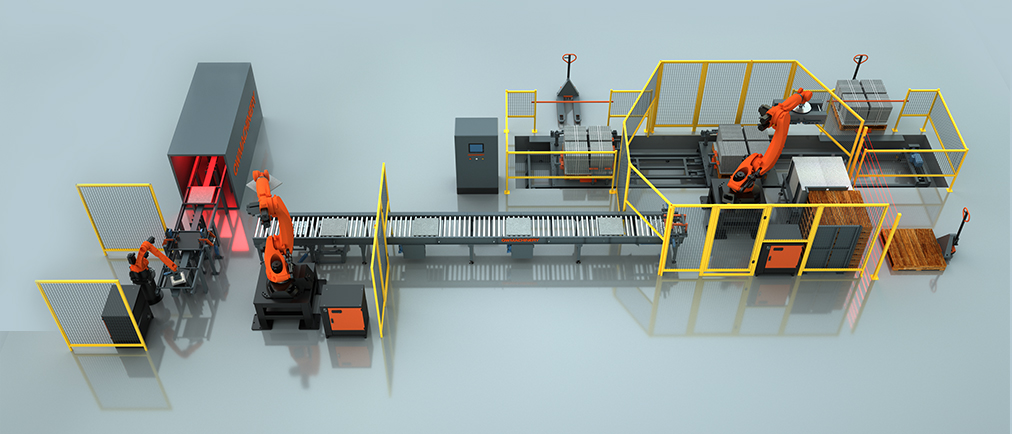

Tile De-Moulding+Mould Cleaning & Oiling+Tile Palletizing

Tile De-Moulding+Mould Cleaning & Oiling+Tile PalletizingOverall displayThe whole solution consists of Robot de-moulding the tile from the mould, Robot clean & oil the mould, Robot does tile palletizing.Operation ProcessSave labor & Improve effeciencyManual WorkVSRobotic Automation

Contact us and ask more

Message from users: the machine is very easy to use and the installation team is professional, serious and responsible

-

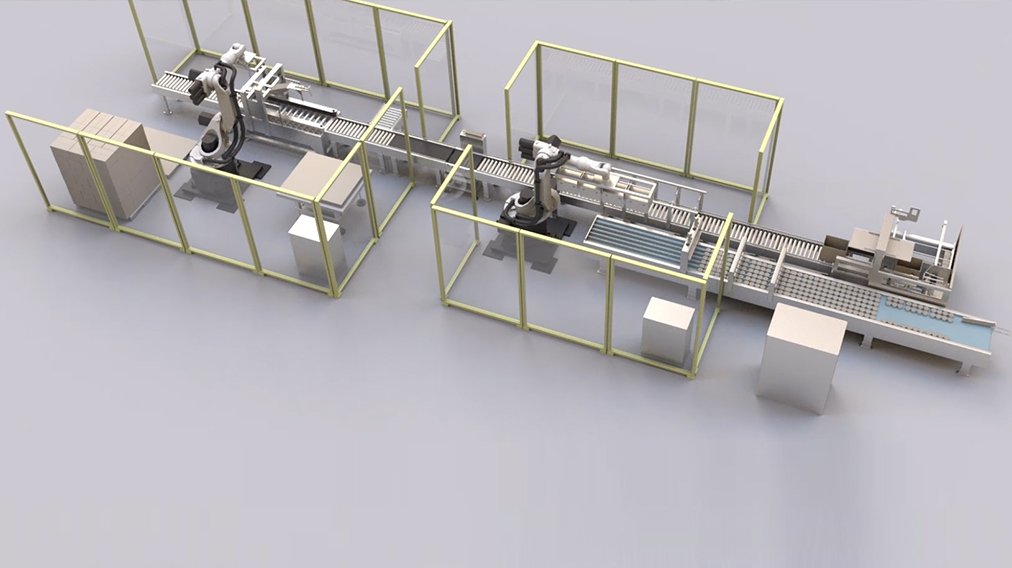

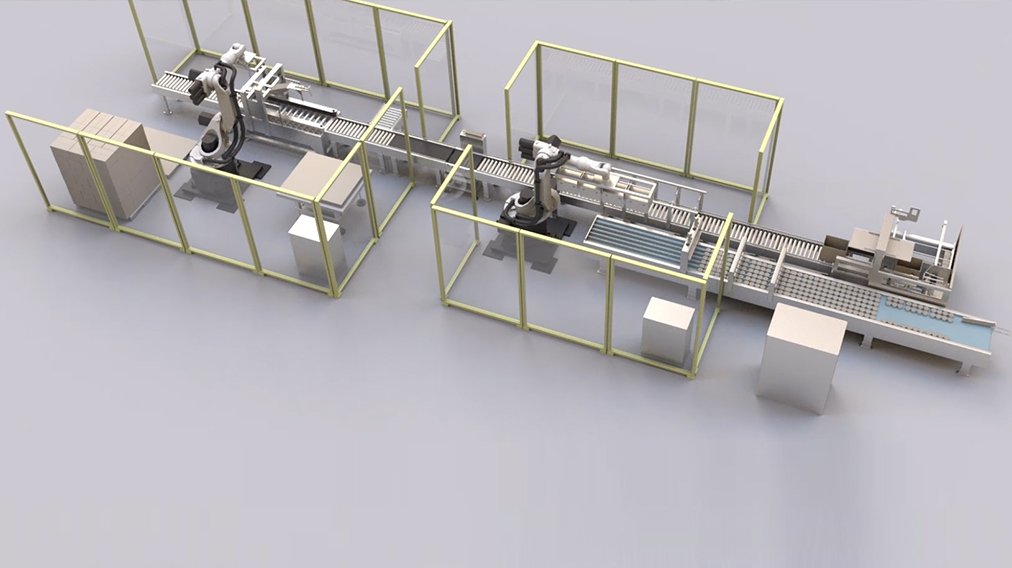

Automatic Sugar Sachet Packaging Line

Automatic Sugar Sachet Packaging LineThe whole system consists of 3 sets QW-D3P-1100 3+1 axis parallel robots at the speed 260pcs per minute. The parallel robot will pick the sugar sachets from the conveyor and then put into the cartoning machine feeding conveyor.

Contact us and ask more

Message from users: the machine is very easy to use and the installation team is professional, serious and responsible

-

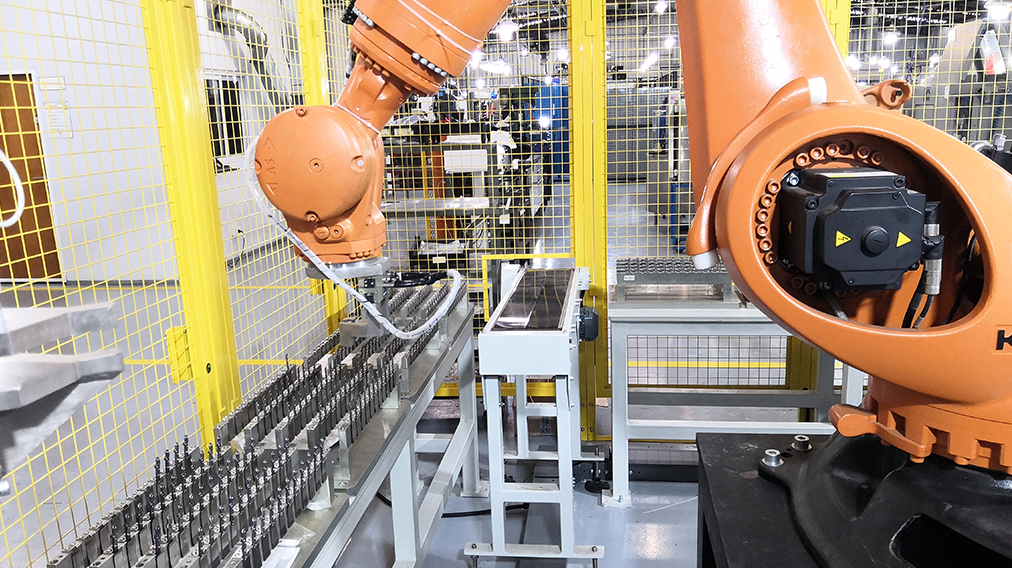

Robotic case packer & palletizing

Contact us and ask more

Message from users: the machine is very easy to use and the installation team is professional, serious and responsible

-

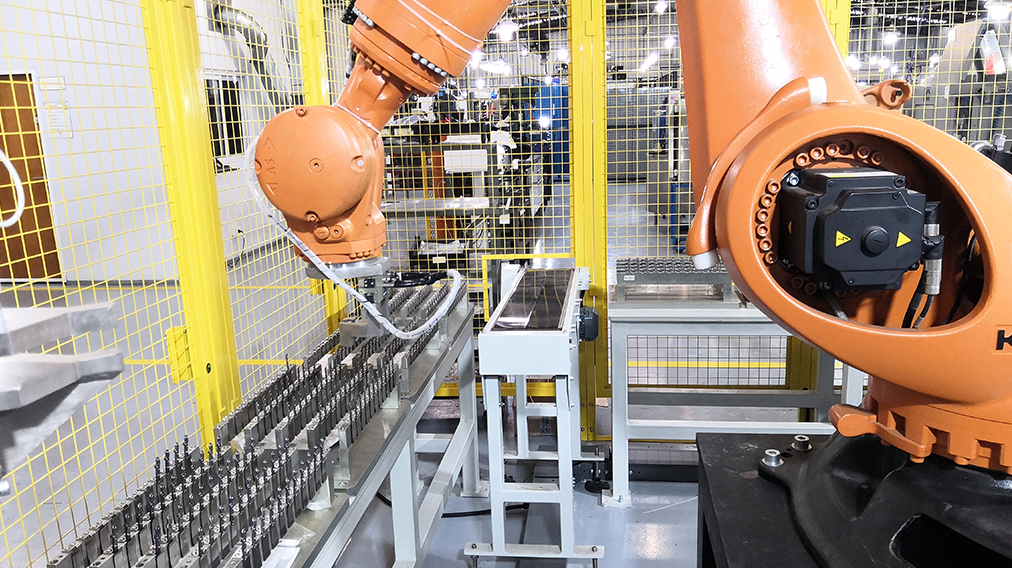

Robotic Orthopedic Implants Polishing System

Robot applicationThe following are polishing implants for metal implants in Argentina. Customers have a total of nine different shapes and sizes of products, facing long manual processing time, low precision of finished products, and different standards for different people after processing.We design a robot grinding system after production. The finished product standard is uniform, which meets the high precision requirements of medical supplies and has high efficiency. A robotic grinding system...

Contact us and ask more

Message from users: the machine is very easy to use and the installation team is professional, serious and responsible

-

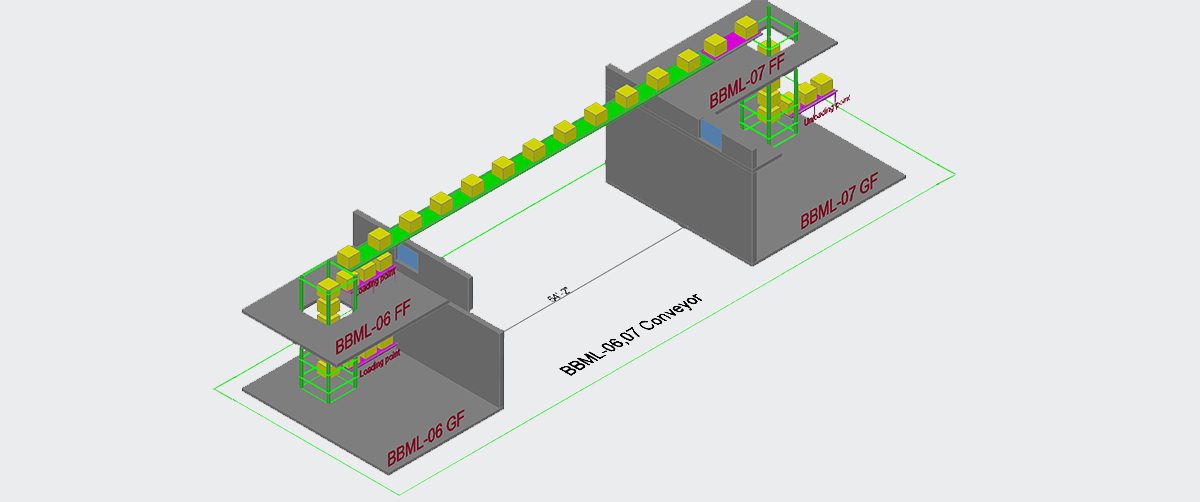

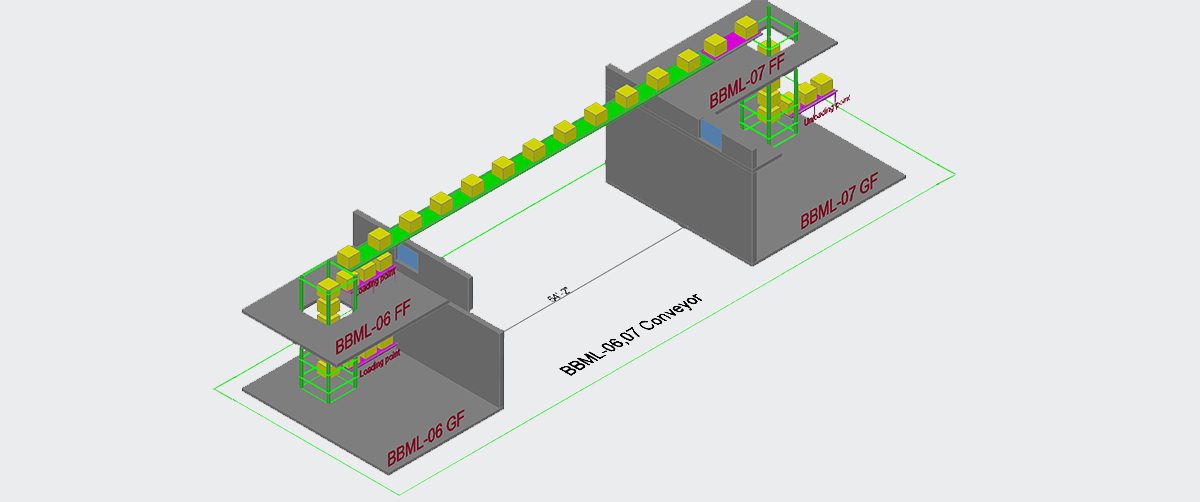

Vertical Conveyor System

Before installing our vertical conveyor, people will manually to pull the pallet full of cartons and other irregular products from one building workshop to another building warehouse.After installed our vertical conveyor, they realize to conveying the cartons and other irregular products from one building to another building. They not only conveying inside one building from Ground floor to 3rd floor, but also conveying between two buildings by using two sets Vertical conveyor +...

Contact us and ask more

Message from users: the machine is very easy to use and the installation team is professional, serious and responsible